Production & Capabilities

Precision, Flexibility, and Cell Culture

To meet the evolving demands of the cell culture market, Capricorn Scientific provides high-performance manufacturing solutions with a focus on quality, scalability, and flexibility.

Our 1,350 m² state-of-the-art production facility, established in 2022, ensures strict quality control, regulatory compliance, and process reliability for biotech, research, and biopharma applications.

Facility Design & Quality Standards

Our production site is designed to ensure absolute product integrity, with a 350 m² dedicated cleanroom area and strict spatial separation of animal-derived and chemically defined media:

- Lower Level →

Dedicated to animal component-free manufacturing of chemically defined media, eliminating any risk of cross-contamination. - Upper Level →

Specialized in animal component-containing products, including Fetal Bovine Serum (FBS) and other serum-based formulations.

This separated infrastructure, combined with GMP-compliant manufacturing standards, ensures the highest level of purity, safety, and batch-to-batch consistency for all our cell culture products.

Serum Processing & Customization

Serum plays a critical role in cell culture, providing essential growth factors, hormones, and nutrients. Capricorn Scientific specializes in:

- Processing animal sera from various origins, ensuring full traceability and ethical sourcing.

- 0.1 µm sterile filtration and rigorous quality control to maintain batch-to-batch consistency.

- Custom serum solutions, including heat inactivation, gamma irradiation, and specialized formulations.

- Strict separation of serum production from our media and reagents facility to prevent cross-contamination.

Our expertise in serum processing and formulation development makes us a trusted partner for research, diagnostics, and large-scale biopharma applications.

Cell Culture Media Production

Capricorn Scientific offers a broad portfolio of classical, chemically defined, and custom media to support a wide range of applications, including:

- Standard formulations → DMEM, RPMI 1640, MEM, and other industry-standard media.

- Protein-free & chemically defined media → Designed for specialized research and industrial-scale bioproduction.

- Cytogenetic & cell-type-specific media → Optimized for lymphocytes, amnion, and bone marrow cultures.

- Custom media development → Tailored to your process requirements and cell line needs.

We accommodate production volumes from R&D batches to full-scale commercial manufacturing, with fill sizes ranging from small bottles to 1,000 L single-use containers. All media production follows strict animal-free protocols in a dedicated facility.

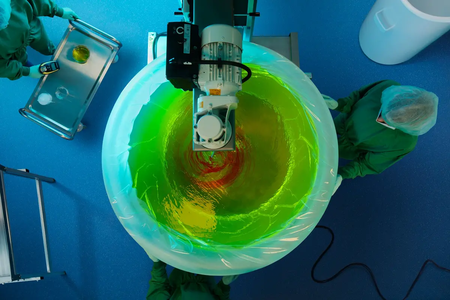

Powder Media & Dry Formulations

To support bioprocessing, large-scale production, and flexible research needs, Capricorn Scientific has invested in cutting-edge dry powder manufacturing technologies. Our Express Response Media Service allows us to provide:

- Basal media & buffer formulations in dry powder format for increased shelf life and storage efficiency.

- Advanced pin milling & blending technology, ensuring homogeneous distribution of nutrients and components.

- Large-scale biopharma production as well as fast, small-batch custom manufacturing.

- Fully controlled, monitored, and traceable production from raw materials to final product.

Our dry powder production capabilities allow for fast delivery, superior solubility, and process flexibility, making us a trusted partner in biomanufacturing.

Ready to Order or Need Expert Advice?

Whether you're looking for ready-to-use cell culture products or require a customized solution, our team is here to assist you. Get in touch with us today to discuss your requirements and find the perfect fit for your research or production needs.